Quality assurance

MegaMETA Quality Inspection Capabilities

We combine cutting-edge metrology, strict calibration standards, and expert technicians to ensure your parts meet the highest industry standards.

Thread Gauges (Metric, BSPS, UNF, NPTF)

Used to verify thread pitch, diameter, and profile, our certified thread gauges ensure precise mating and conformance with mechanical standards for both internal and external threads.

Micrometers & Bore Gauges

Our precision micrometers, including three-point bore micrometers, allow highly accurate measurement of internal diameters and critical tolerances across various geometries.

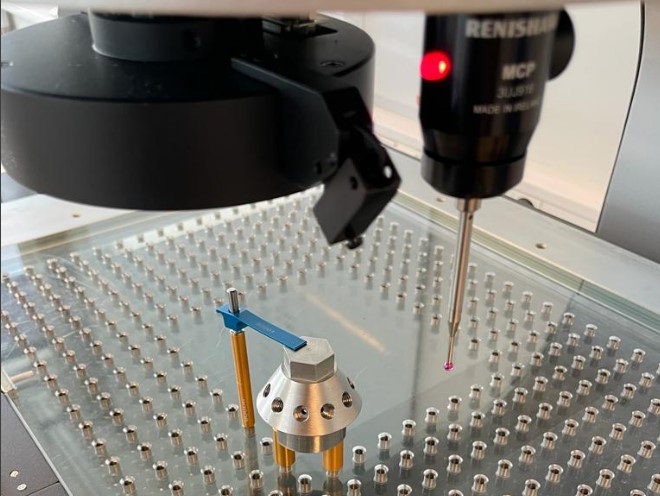

CMM with Scanning Probe

Hexagon Lite with Scanning Probe and CAD++ is a compact CMM solution offering precise 3D scanning and powerful CAD-based inspection for efficient quality control and reverse engineering.

VMM & CMM Technology

A hybrid solution combining optical vision and precision probing for comprehensive, high-accuracy dimensional inspection across complex parts.

Surface Roughness Testing

We use profilometers and surface roughness testers to assess finish quality and compliance with Ra specifications for functional and aesthetic performance.

Hardness Testing

Using Rockwell, Vickers, and Brinell methods, we evaluate material resistance to wear, ensuring durability and reliability in final applications.

Paint Thickness Control

To ensure proper coating application and protection, we perform paint thickness checks that align with visual and corrosion resistance standards.

Spectro analysis (External Lab)

We partner with trusted analytical labs to verify chemical composition through spectro analysis — ensuring full traceability and compliance with alloy standards.

Commitment to Calibration & Accuracy

All measurement tools are calibrated regularly in accordance with ISO quality procedures. This guarantees every inspection result is accurate, reliable, and audit-ready.

MegaMETA – Where Precision Meets Trust.